Have you ever found yourself in the middle of a plumbing project, puzzled about which flanges to use? I remember a particularly challenging day when an unexpected leak in my neighbor’s basement led me down the rabbit hole of flanges. I discovered the MLX flange, an unsung hero in the world of plumbing, that not only simplified installation but also brought immense benefits. In this article, we’ll explore what makes MLX flanges stand out, how to install them, and tips to keep your plumbing projects running smoothly.

Understanding the MLX Flange

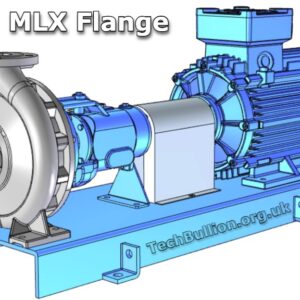

Have you ever wondered what an MLX flange is? It’s a specialized component that plays a crucial role in various piping systems. So, what exactly is it?

Definition and Basic Functions of MLX Flanges

An MLX flange is designed for strength and durability. At its core, it serves to connect pipe sections, valves, and pumps in a system. This connection is vital for the flow of liquids or gases. Think of it as the glue that holds everything together.

Besides connection, flanges help in maintenance. They allow easy disassembly when repairs are needed. This functionality makes them handy in both plumbing and industrial settings, like oil and gas production. Understanding its primary functions helps you appreciate its significance.

The Materials Used and Their Significance

What materials are MLX flanges made from? The most common choices are carbon steel and stainless steel. Each offers unique benefits:

- Carbon Steel: Known for its strength, it’s generally used for heavier applications.

- Stainless Steel: Excellent for resisting corrosion. This is crucial in industries where moisture and chemicals are prevalent.

The choice of material significantly affects performance and longevity. For instance, using stainless steel in corrosive environments extends the life of the flange, thus saving costs over time. It’s always a matter of choosing the right tool for the job.

Common Applications in Various Industries

MLX flanges find widespread use in HVAC systems and piping. They also appear in oil and gas, where strength is paramount. Why? Because in high-pressure scenarios, a reliable connection prevents leaks. A failure here can be catastrophic.

The quote rings true:

“The right flange can make or break the integrity of a system.” – Industry Expert

It highlights the importance of selecting appropriate flanges for specific needs.

Material Types and Their Usage

| Material Type | Common Applications |

| Carbon Steel | Heavy-duty piping, construction, industrial frameworks |

| Stainless Steel | Food processing, pharmaceuticals, water treatment |

In summary, understanding what an MLX flange is and its role in various applications is essential for anyone involved in plumbing or industrial systems. It’s intriguing how such a small component can have such a large impact on system reliability and maintenance.

Benefits of Using MLX Flanges

Are you searching for a reliable solution for your plumbing needs? Look no further than MLX flanges. They offer numerous benefits that can enhance your projects significantly. In this section, we explore these advantages to help you understand why MLX flanges are a wise choice.

1. Enhanced Durability and Strength

One of the most notable benefits of MLX flanges is their durability. Did you know that using these flanges can extend the lifespan of your installations by up to 50%? This means fewer replacements and repairs are needed over time. Imagine how much time and money you could save!

Furthermore, their strength makes them suitable for various applications. You can trust MLX flanges to withstand high pressures and harsh conditions. This reliability translates into peace of mind for you as a homeowner or contractor.

2. Cost-Effectiveness in the Long Run

Investing in MLX flanges is like taking a financial shortcut. Their cost-effectiveness stands out here. Reports show that you can save approximately 20% compared to traditional flange models. Doesn’t that sound appealing?

When you think about the future, remember that upfront costs aren’t the only consideration. The durability and reduced need for maintenance will lower ongoing expenses. Hence, you won’t just save at the outset; you will continue saving long after the purchase.

3. Ease of Maintenance and Installation

Installation and maintenance should never feel like a chore. With MLX flanges, they don’t have to! These flanges are designed for ease of installation. This means you can complete projects faster, leaving you more time for your other endeavors.

Imagine finishing a plumbing job in half the time! Easy installation also leads to quicker turnarounds on projects something that pleases both contractors and customers.

Summary Table of Key Benefits

| Benefit | Data |

| Durability | Can extend lifespan by up to 50% |

| Cost-effectiveness | Approximately 20% savings over traditional models |

“Investing in a quality flange pays for itself through reduced maintenance costs.” – Plumbing Specialist

This quote summarizes it perfectly. Quality and cost-effectiveness go hand in hand! So, are you ready to embrace the advantages that MLX flanges bring to your projects? They not only enhance your work’s durability but also save you money and time in the long run.

Step-by-Step Installation of MLX Flanges

Installing MLX flanges can be straightforward if you follow the right process. However, having the right tools and materials is just as important as following the steps. Let’s dive into what you need and how to successfully install them.

Tools and Materials Needed for Installation

Before you start, gather the essential tools and materials:

- Wrenches: These come in handy for tightening bolts.

- Screwdriver: Needed for assembling parts accurately.

- Level: To ensure that everything is aligned correctly.

- Flange Gasket: Essential for a leak-proof installation.

- Pipe Thread Sealant: This prevents leaks at the threaded connections.

Precise Steps to Ensure Proper Fitting

Now, let’s break down the steps to install your MLX flanges properly:

- First, clean the flanges: Remove any old materials or dirt.

- Install the gasket: Place it between the two flanges.

- Align the flanges: Make sure they fit together perfectly.

- Tighten the bolts: Use a crisscross pattern for even tightening.

- Final check: Make sure everything is level and snug.

With these steps, you’re well on your way to a successful installation.

Common Mistakes to Avoid During Setup

Even the best can make mistakes. Here are some you should avoid:

- Skipping the cleaning step: Always clean your flanges before installation.

- Incorrect gasket placement: Ensure the gasket is centered properly.

- Over-tightening bolts: This can warp the flange and lead to leaks.

Safety Tips and Best Practices

Safety should always be a priority. Here are some best practices:

- Wear protective gear: Gloves and goggles can prevent injuries.

- Work in a well-lit area: Good visibility makes the job easier.

Did you know that proper planning can cut installation time by 30%? If you make sure you have everything ready in advance, the whole process becomes quicker.

“Proper installation is half the battle won in plumbing projects.” – Veteran Plumber

With these tips in mind, you’re set for a successful MLX flange installation. Remember to take your time. Rushing can lead to mistakes, but a well-executed installation saves you future headaches.

Real-Life Scenarios: Success with MLX Flanges

When it comes to plumbing and installations, the tools you use can make all the difference. Many professionals have switched to MLX flange, and the results speak for themselves. Let’s dive into some case studies and stories that showcase this transformation.

Case Studies from Professionals

One local contractor shared their experience. They said,

“Switching to MLX flanges transformed my plumbing business.”

Before the switch, they struggled with complicated installations that cost time and money. After moving to MLX, they found that the process became much smoother. Imagine cutting down your installation time by hours. That’s what these flanges can do.

Another success story comes from a team of HVAC professionals. They reported a significant reduction in leaks after using MLX flanges. Their feedback suggests that the tight seal provided by these flanges ensures better performance and reliability. Their clients even noticed fewer callbacks for repairs!

Relatable DIY Stories

For those of you who fancy yourself as DIY enthusiasts, there’s plenty to learn from real-life stories too. Take, for example, a homeowner named Jake. Jake faced a daunting task: replacing old, worn-out flanges. After researching options, he stumbled on MLX flanges. Armed with a bit of guidance, he tackled the installation himself. What did he find? They were easier to work with than expected. No more struggling with poorly fitting parts!

His peers looked on in admiration. “If Jake can do it, so can I,” they said. The ease of installation prompted several friends to switch, further spreading the word about MLX flanges.

Insights Gained Through Experience

What do these stories tell us? First and foremost, they highlight the importance of choosing the right tool. Installers report that about 75% of users say the installations go smoother after switching to MLX. This is vital information whether you’re a seasoned pro or just getting started.

Insights gained from experience show that investing in quality products pays off. It’s not just about the installation; it’s about long-term performance. Users appreciate the reliability of MLX flanges and the way they minimize hassle. Feedback from various users points towards enhanced performance, leading to fewer issues down the line.

Switching to MLX means fewer headaches, smoother installations, and a lot more confidence in completing plumbing projects successfully.

Challenges and Considerations When Using MLX Flanges

When working with MLX flanges, you might encounter several challenges. It’s essential to understand these hurdles to ensure successful installation and longevity.

1. Installation Issues

One common problem arises when flanges are not installed correctly. This mistake can lead to leaks, which can be both troublesome and costly. Did you know that 27% of plumbing failures occur due to flange issues? That’s a significant number!

- Ensure all surfaces are clean before installation.

- Use proper tools and techniques to secure the flanges.

- Don’t rush the process, as attention to detail is crucial.

“Attention to detail during installation is critical for avoiding future problems.” – Expert Consultant

2. Compatibility with Other Components

Another consideration is the compatibility of MLX flanges with other plumbing components. You wouldn’t want to choose a flange that’s not compatible with your pipes, right? This situation can create a host of issues.

- Check the materials used for both flanges and pipes.

- Verify sizes and types before committing to installation.

For example, if you select a flange that doesn’t match your pipe diameter, it could lead to leaks and eventual system failures. Always double-check compatibility before you start.

3. Environmental Factors

Finally, don’t overlook environmental factors. Temperature fluctuations, moisture levels, and even soil conditions can affect flange performance. Understanding these conditions will help you make better choices.

- Consider using flanges designed for high-temperature environments.

- Protect flanges from moisture to prevent corrosion.

Being aware of these challenges and considerations when using MLX flanges is crucial. The mistakes could mean costly repairs or a replacement down the road. Therefore, it’s smart to be meticulous and thorough. After all, you want a reliable, leak-free plumbing system.

Understanding the pitfalls and how to avoid them is critical for success. Whether you’re a seasoned plumber or a DIY enthusiast, a proactive approach will serve you well in the long run.

Conclusion: Embracing the Benefits of MLX Flanges

In wrapping up our discussion on MLX flanges, it’s essential to revisit the key benefits highlighted throughout this blog. First and foremost, MLX flanges offer exceptional durability. This means they withstand pressure and temperature changes effectively. You can count on them even in the most demanding environments. Isn’t that reassuring?

Moreover, these flanges are designed with installation efficiency in mind. When you consider the time and cost saved from quicker installation, the choice becomes clearer. It’s like having the right tool for the job everything just fits better. Plus, their compatibility across various systems allows for flexibility. This can save you from the hassle of searching for multiple products.

Final Installation Tips

As you delve into the installation process, remember these final thoughts:

- Always ensure that surface conditions are optimal before installation. Clean, flat surfaces contribute to a better seal and longevity.

- Don’t rush the tightening process. Proper torque specifications help you avoid leaks later on.

- Check for compatibility. Not all flanges fit all systems, so double-checking can save you time down the road.

These tips can make a world of difference. Taking the time to follow them can enhance the connection strength and increase the lifespan of your installation.

Your Next Steps

Now, are you ready to consider integrating MLX flanges into your projects? The benefits are compelling. From their durability to the ease of installation, MLX flanges might be just what you need. If you’ve been skeptical, now is the time to give them a shot. The potential for increased efficiency and reliability is too good to miss.

Think about how these advantages can transform your work processes. With improved performance and reduced risks, embracing MLX flanges could elevate your projects to a new level. Reflect on the shared information and imagine its impact. Are you ready to turn these insights into action? Your project deserves the best.

Frequently Asked Questions About MLX Flanges

MLX flanges are an essential component in many industries. You might wonder, what are the most common uses of MLX flanges? They are widely used in chemical processing, oil and gas, and water supply systems. Their design is crucial to maintaining pressure and preventing leaks. For example, in pipelines carrying hazardous materials, a solid connection is non-negotiable. Otherwise, safety risks increase dramatically.

1. Common Uses of MLX Flanges

- Chemical Processing: MLX flanges are often utilized in equipment like reactors and heat exchangers. They help to seal connections and minimize leaks.

- Oil and Gas Industry: In this sector, MLX flanges ensure secure connections in high-pressure environments.

- Water Supply Systems: You’ll find MLX flanges in valves and piping for managing clean and wastewater lines.

This broad range of applications demonstrates why MLX flanges are favored in various settings. But how do these flanges compare to other types? That’s an important question to ask.

2. Comparison to Other Flanges

MLX flanges stand out due to their specific material composition and design. Compared with standard flanges, MLX flanges offer increased durability and resistance to corrosion. This makes them a better choice for harsh conditions.

Other flange types, such as weld necks or slip-on flanges, might be less robust. They serve their purposes but fall short under extreme conditions often faced in industrial applications. When choosing, it boils down to a matter of safety and longevity. Remember,

“Knowledge is power when it comes to flange selection.” – Industry Leader

3. Lifespan of MLX Flanges

Considering an MLX flange? You probably want to know about its lifespan, right? On average, MLX flanges can last between 10 to 30 years. This duration varies based on usage conditions. For instance, factors like pressure and temperature can influence wear and tear.

In summary, understanding the applications, comparisons, and lifespan of MLX flanges helps you make informed decisions. Keeping these insights in mind can guide you toward selecting the right flange for your needs.